+86 186 7553 4520

+86 186 7553 4520 jiayonghuang03@gmail.com

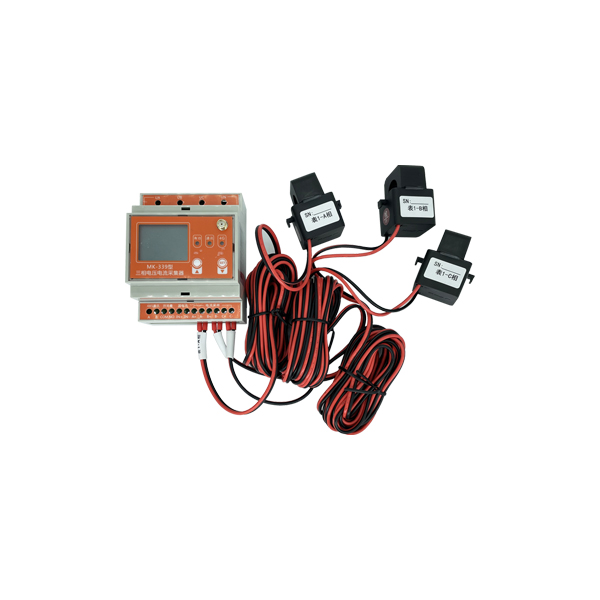

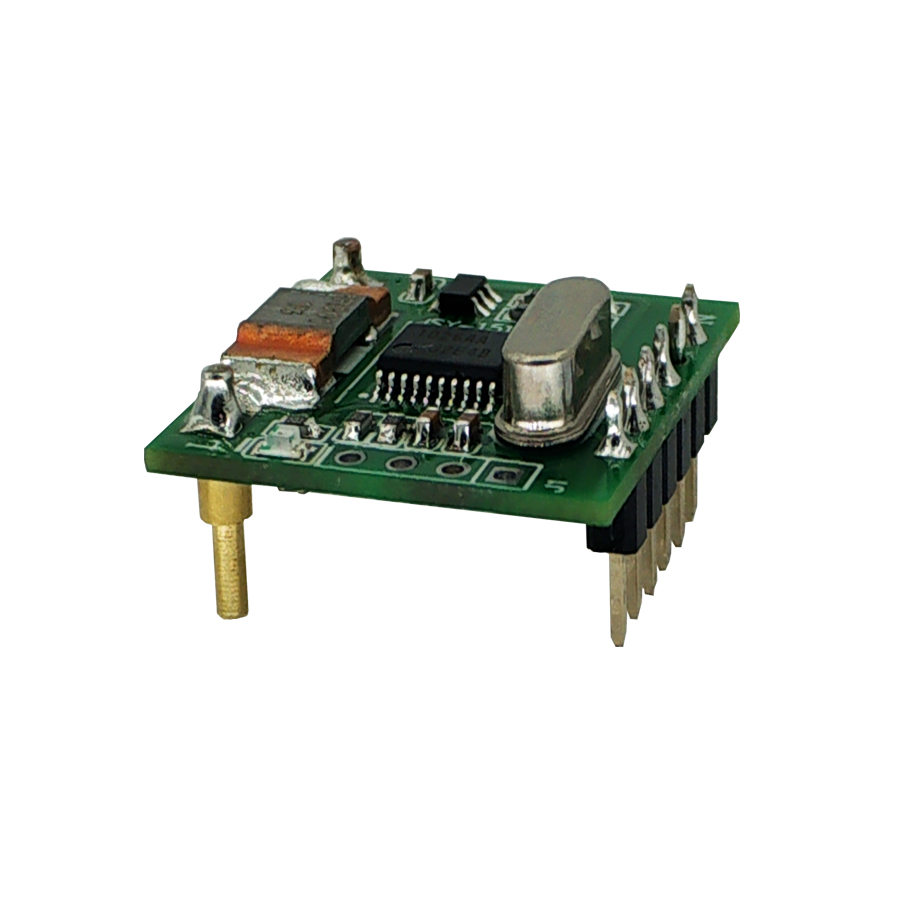

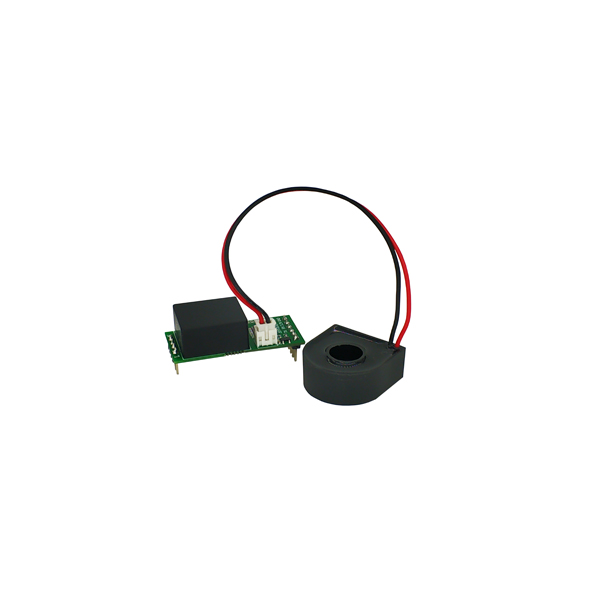

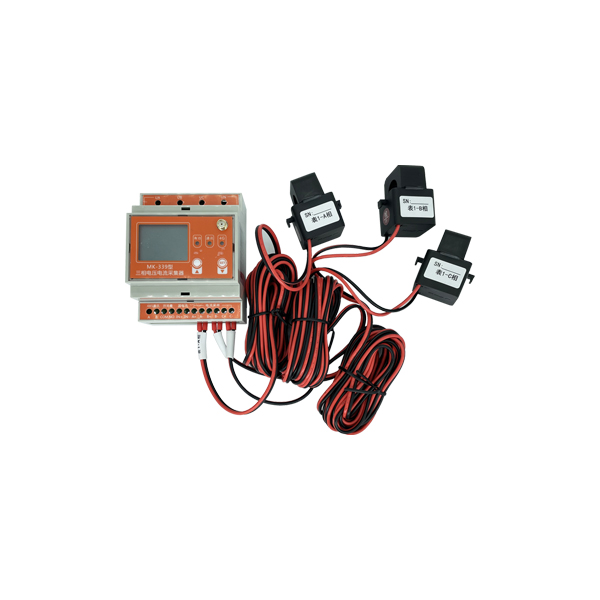

jiayonghuang03@gmail.comJsy-mk-229 DC charging pile electric energy measurement module aims at the inconvenience of the traditional wall mounted electric energy meter in the field use and installation, and designs a miniature guide rail mounted electric energy meter, which has the advantages of high measurement accuracy, strong overload capacity, stable and reliable performance, wide working voltage range and low power consumption. And its small size, light weight, modular structure, can be used with miniature circuit breakers installed in the distribution box to achieve terminal distribution energy measurement.

1. Strong current and weak current isolation;

2. The measurement accuracy meets the international standard level 1;

3. One 485 communication interface;

4. The shell adopts 2p guide rail shell;

5. Wide voltage 12-36vdc working power supply;

6. Shunt with different current specifications can be selected;

7. Highly integrated electric energy measurement and digital communication can replace traditional electric energy meters

8. Support personalized customization;

1. Measurement

1.1 measurement type: AC / DC adaptive;

1.2 voltage range: 1-1000v;

1.3 current range: 0.02-300a, shunt optional;

1.4 voltage resolution: 0.001V;

1.5 current resolution: 0.0001a;

1.6 electric energy resolution: 0.001kwh;

2. Communication

2.1 interface type: RS485 communication, built-in ESD protection;

2.2 communication protocol: Modbus RTU protocol;

2.3 data format: n, 8,1;

2.4 baud rate: 1200-9600bps, 9600bps by default;

2.5 communication interval: once a second;

3. Performance

3.1 typical power consumption: ≤ 20mA;

3.2 working power supply: external power supply, 12-36vdc power supply;

3.3 withstand voltage level: the tested power supply and the power supply are isolated from each other, and the isolation withstand voltage is 4000vdc;

3.4 overload capacity: 1.2imax sustainable;

4. Operating environment

4.1 working temperature: -30~+70 ℃, storage temperature -40~+85 ℃;

4.2 relative humidity: 5~95%, no condensation;

4.3 working environment: places without explosion, corrosive gas and conductive dust, and places without significant shaking, vibration and impact;

4.4 installation method: 2p35mm guide rail installation;