- With the popularization of green travel concepts and the rapid development of the electric bicycle market, the demand for bicycle charging piles is growing. As the core component of bicycle charging piles, the design and manufacturing quality of PCB (printed circuit board) is directly related to the performance, safety and reliability of the entire charging equipment. This article will discuss the layout considerations and manufacturing difficulties of bicycle charging pile PCB.

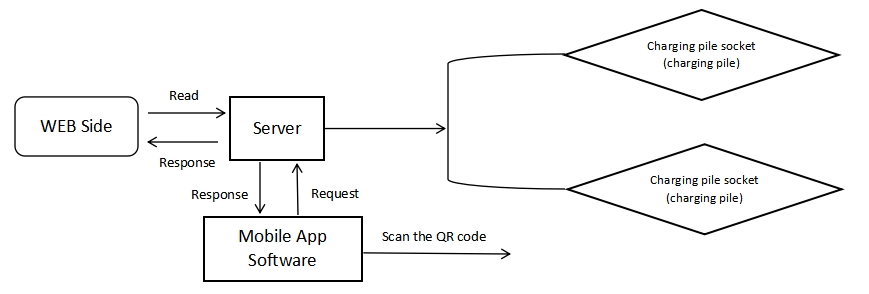

- What is a bicycle charging station: A bicycle charging station is a device that provides charging services for electric bicycles. It is usually installed in public places such as residential areas and shopping malls, and supports charging multiple electric bicycles at the same time. It has a self-stop function when fully charged to ensure charging safety, and through intelligent management, it is convenient for users to view charging status and consumption details.

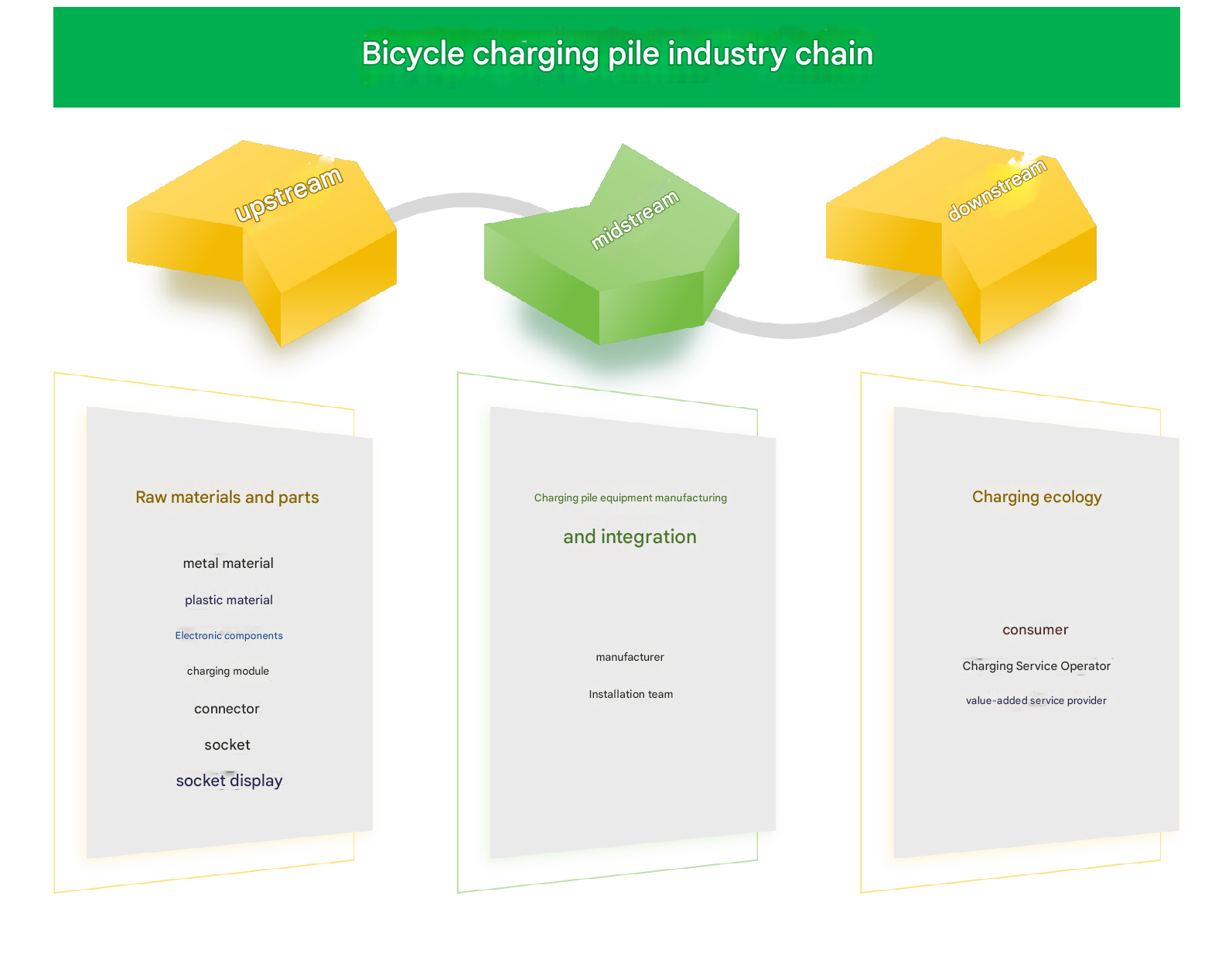

- Let us take a look at the upstream and downstream industries of the bicycle charging pile industry and the related industry overview.

- It can be clearly observed that the upstream industry mainly focuses on the production of materials themselves and related products and equipment, while the midstream industry mainly focuses on the production and installation of bicycle charging piles, and its technical details and process requirements are more critical. Entering the more detailed mid- and downstream fields, we can find its close connection with the PCB industry (printed circuit board industry). Finally, the downstream industry covers a variety of applications and services to meet the diverse needs of the market.

- Take the lithium battery we are familiar with as an example, because various control systems, such as lithium battery and other charging pile products, require PCB to implement.

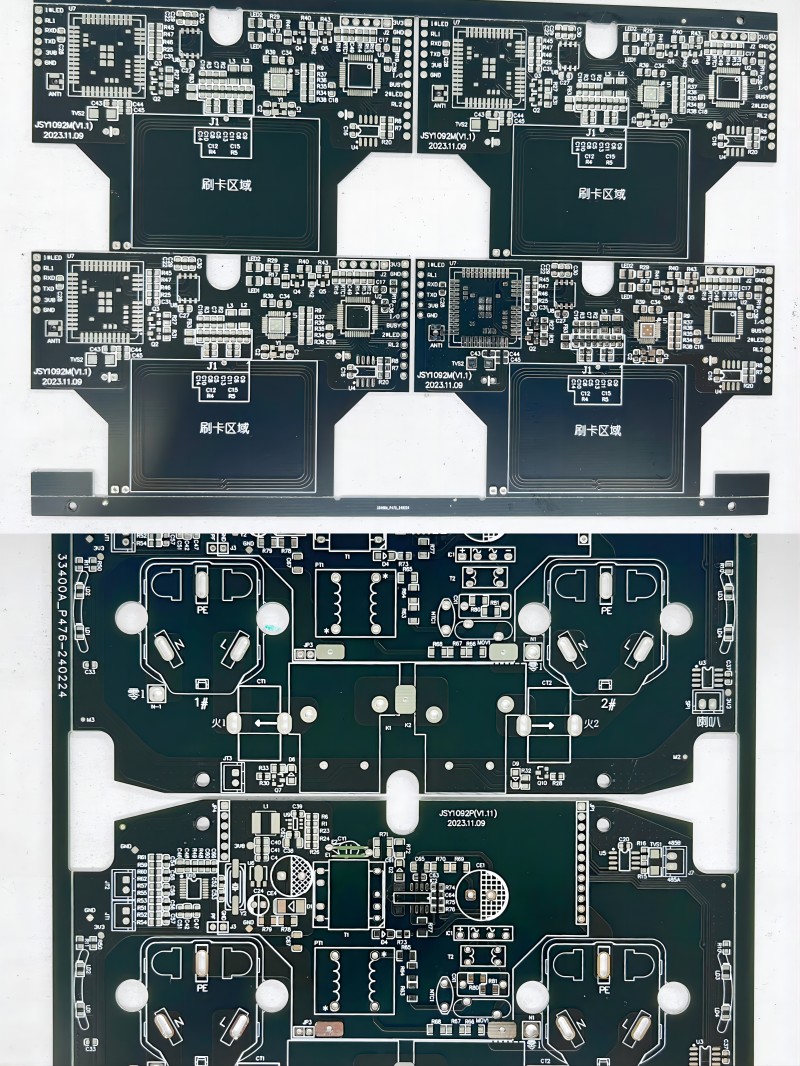

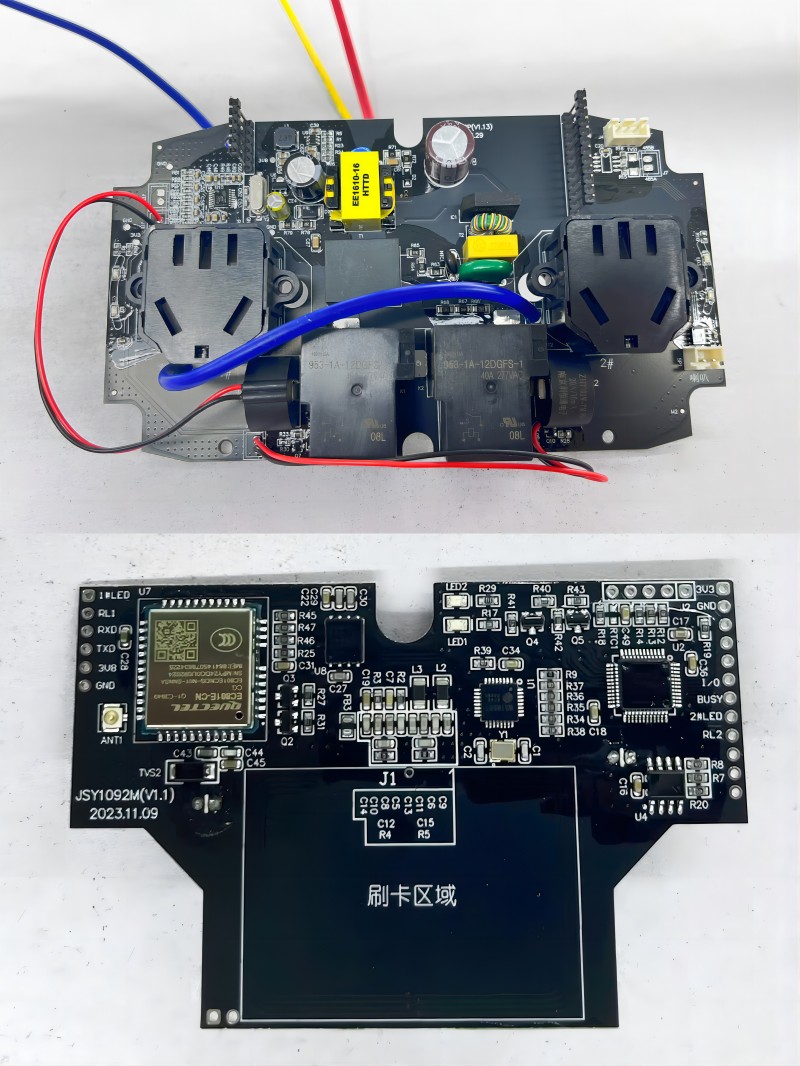

- So what are the PCB products in the bicycle charging pile industry like? The editor specially found several charging pile boards of our JSY-MK-1092 for everyone to see, which are as follows.

Post time: Nov-30-2024